The SBORAEK (Smart Ballistic Optimization for Repairing of Aerospace Exostructures using 3D-printed Kevlar) is set to revolutionise repair procedures for aerospace structures. Led by Dr Leonardo Barilaro, Senior Lecturer in Aerospace Engineering at the Malta College of Arts, Science, and Technology (MCAST), the project is funded by the Malta Council for Science & Technology through the FUSION—Technology Development Programme LITE.

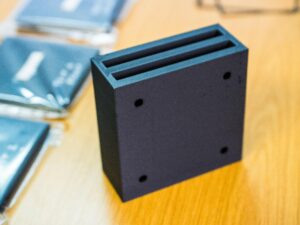

Inspired by Börek, a savoury traditional Turkish pastry made with thin, flaky yufka dough (likely from the Turkic word “bur”, meaning “to twist”), the project’s acronym reflects the smart methodology used to create layered structures. The SBORAEK shields utilise an innovative 3D printing method using continuous aramid fibre materials like Kevlar® and carbon fibre.

Maintaining the structural integrity of aircraft and spacecraft is paramount for safety. Current repair methods can be time-consuming and expensive, especially for damage caused by high-energy impacts from micrometeoroids or space debris. SBORAEK proposes a novel solution using 3D printing technology to create custom repair patches.

This project, which is also supported by MCAST’s Institute of Engineering and Transport (IET), holds the potential to minimize downtime and repair costs through on-site repairs, achieve superior customisation that reduces wasted materials and weight, improve overall repairability, and find applications beyond traditional aviation in the modules of the International Space Station and future spacecraft.

The core of SBORAEK lies in its three main goals: developing a method to optimise the design of 3D-printed shields for superior ballistic performance, creating custom repair patches using 3D-printed continuous aramid fibres combined with other materials for enhanced functionality, and ultimately reducing MRO (Maintenance, Repair, and Overhaul) time by streamlining the repair process.

The project was presented at several international occasions, including the International Astronautical Congress 2023 (Baku, Azerbaijan), the AIDAA 2023 conference (Padua, Italy), and Khalifa University (Abu Dhabi, UAE).

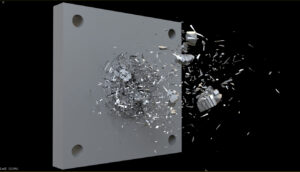

SBORAEK culminated in a series of tests conducted in collaboration with Thiot Ingenierie (France), their Hypervelocity Impact facility features a Light-Gas Gun, which was used to assess the ballistic performance of 3D-printed Kevlar shields designed for aerospace applications.

SBORAEK’s success hinges on the collaboration between MCAST, CISAS of the University of Padova (Italy), and Skyup Academy (Italy). This combined expertise in aerospace engineering, materials science, innovative simulations, and 3D printing technology paves the way for a significant advancement in aerospace repair.

MCAST’s Institute of Engineering and Transport (IET) offers a wide range of aviation educational programmes of study. Applicants interested in launching or advancing their studies within this sector can download the MCAST prospectus and apply online via the College website.

For more info, visit the SBORAEK website – mcast.edu.mt/sboraek

MCAST Main Campus

MCAST Main Campus  +356 2398 7100

+356 2398 7100

information@mcast.edu.mt

information@mcast.edu.mt